Shurflo Pump Pressure Switch: Full Handbook & Advice

Did you know the Shurflo Pump pressure switch typically shuts off at 55 psi but can self-prime up to 6 feet? Grasping how the Shurflo Water Pump pressure switch works is essential for those aiming to enhance liquid flow in RVs and other systems. This detailed guide offers recreational vehicle owners, installers, and do-it-yourself aficionados with in-depth insight. It addresses the pressure switch’s functionality, calibration techniques, setup processes, and maintenance tips. This Shurflo pressure switch content is vital whether you’re fixing an issue or boosting your pump’s efficiency.

Main Takeaways

- The pressure switch can shut off at 55 psi for optimum performance.

- Bypass mechanism starts opening at 30 psi and is fully open at 65 psi.

- Take care to avoid pressure overlaps between bypass and shut-off that may cause issues.

- Its adjustable settings allow customization to match system requirements.

- A minimum of 1/2” I.D. tubing is necessary for correct inlet operation.

- Thermal protection mechanisms avert damage by preventing overheating during dry operation.

- Adhere to the 20 minutes per hour intermittent use limit for optimal performance.

Comprehending the Shurflo Pressure Switch for Pump

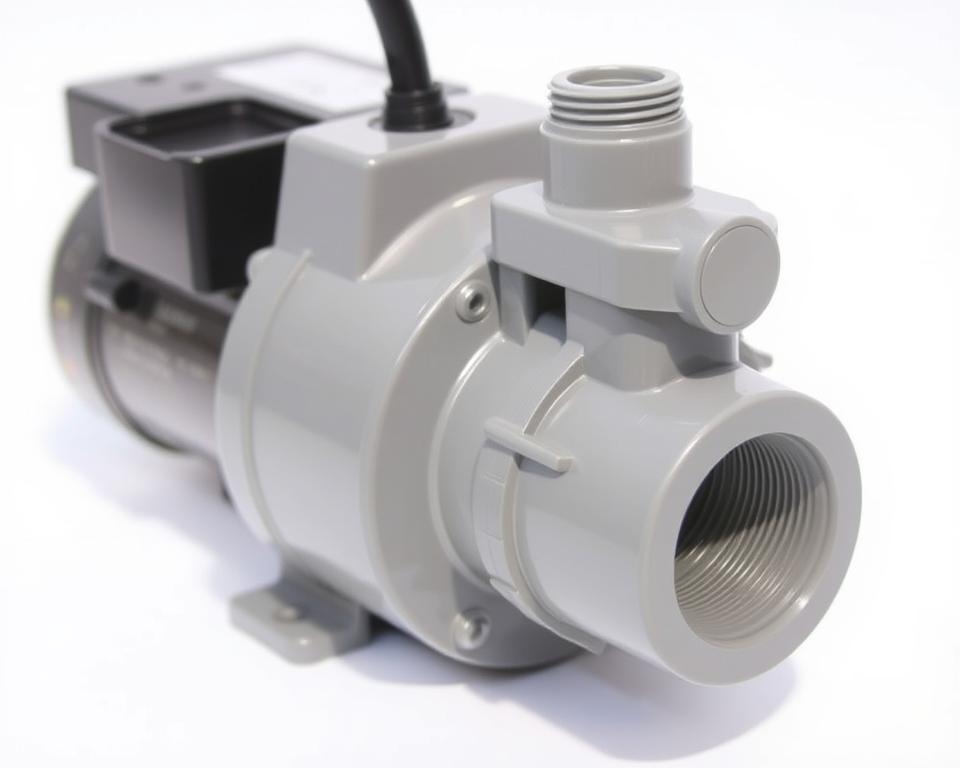

The Shurflo pump pressure switch is crucial in managing Water flow for Pumps. It’s crafted for liquid transfer, essential for recreational vehicles and marine setups. Here, we delve into its purpose, how it works, and its merits in this section.

Definition of the Shurflo Pump Pressure Switch

This pressure switch manages Water system pressure by automatically activating or deactivating the Pump. It engages or disengages the pump based on pressure levels, providing continuous Water flow and safeguarding the Pump from damage due to overuse.

Functionality of the Pressure Switch

The main role of this switch is to monitor Water pressure. It activates the pump if pressure falls, ensuring a constant supply. It deactivates the pump once optimal pressure is reached. This ensures a steady flow but also saves the pump from overworking. The adjustment options allow customization.

Advantages of the Shurflo Pressure Switch

Opting for this pressure switch offers multiple advantages:

- Automatic Operation: It automatically manages water pressure by monitoring real-time data.

- Reduced Energy Consumption: Efficient operation minimizes energy usage by running the pump only as necessary.

- Reduced Wear: It decreases strain on the pump, reducing repair costs over time.

- Consistent Pressure Control: Maintaining the right pressure is essential, particularly in RVs, for consistent water flow.

Its adjustable options make the Shurflo pump pressure switch versatile, fitting various needs, including the shurflo 2095 replacement or other parts.

Installation Advice for Shurflo Pump Systems

Correct installation of your Shurflo pump and its pressure switch is key to optimal performance. This means careful attention to mounting and plumbing is crucial. Doing so helps avoid common problems that could arise during use.

Mounting Guidelines

For best results, install the pump on a stable surface within 6 feet of the Water tank. Such positioning enhances accessibility and performance. When installing vertically, orient the pump head downward to stop liquid from entering the motor chamber.

Using flexible high-pressure hose for the inlet and outlet ports reduces stress and noise and enhances efficient water movement. Sharp tubing bends should be avoided as they may cause kinks and impede flow.

Important Plumbing Tips

The success of the Shurflo pump pressure switch greatly depends on the plumbing. Utilizing a minimum of 1/2″ I.D. plumbing is essential to prevent cavitation. Cavitation can lead to excessive back pressure and diminished flow, so its prevention is key. Installing a 50-mesh strainer on the inlet helps keep debris out of the pump.

Also, keeping the number of elbows and valves in the plumbing to a minimum is advised to lessen flow restrictions. A well-thought-out plumbing layout significantly boosts the efficiency of your Shurflo pump system.

Adjusting the Pressure Settings on Your Shurflo Pump

Proper calibration of your Shurflo pressure switch is essential for optimal operation. Proper calibration assures that your system operates smoothly, reducing the strain on your pump. Start by finding the adjustment screw atop the pressure switch. This screw is key for adjusting the shut-off pressure settings.

Adjusting the Cut-off Point

Rotate the Allen screw clockwise to raise the shut-off pressure—this raises sensitivity, resulting in more frequent pump cycles. This adjustment raises the shut-off threshold to maintain robust pressure. On the other hand, turning the screw counter-clockwise lowers sensitivity and reduces pump cycling.

It’s wise to test your adjustments by running the shower—the pump must run during water flow and shut off when the flow ceases. Set the shut-off pressure to be no less than 10 PSI under the bypass opening level to prevent issues.

Bypass Configuration Explained

Proper bypass configuration is critical to safeguard the switch and enable smooth operation. Adjusting correctly allows water to cycle from discharge back to the inlet at a set pressure. Right bypass settings uphold system efficiency. Excessively high bypass settings may prevent pump shutdown, leading to damage.

Should these adjustments appear challenging, consider consulting an expert. Professional assistance ensures accurate settings and protects system integrity.

Troubleshooting Common Issues

Addressing common issues with Shurflo pumps involves identifying different complications. Problems may arise from both electrical faults and physical component damage. Recognizing these issues is key to troubleshooting and boosting pump efficiency.

Non-starting Pump or Rapid Cycling Issues

If the pump fails to start, first inspect electrical connections. Verify that fuses and switches are functioning properly. Frequent cycling could indicate air leaks or a faulty strainer. Inspect both inlet and outlet valves for blockages that hinder operation. Addressing these pump pressure switch issues is crucial to maintain performance.

Malfunctioning Pressure Switch

A malfunctioning pressure switch could prevent pump activation or lead to constant cycling. Ensure that the switch settings are correct and free of obstructions. If issues persist, replacing the pressure switch might be necessary. Staying alert to these shurflo switch issues ensures reliable pump operation.

Diagnosing Vibration and Noise Issues

Operational noise often signals issues such as loose fittings or improper installation. Make sure that all fittings are secure and the pump is firmly mounted to minimize vibration. Flexible hoses may dampen vibrations, thereby lessening shurflo pump noise issues for a smoother performance.

Caring for Your Shurflo Pump Pressure Switch

Consistent maintenance is key to the optimal performance and longevity of your Shurflo pump. Tasks include cleaning the strainer, detailed inspections, and winter preparations. Proper care enhances its performance and avoids future complications.

Cleaning and Care of the Strainer

Maintaining the strainer is critical to ensure efficient pump operation. Blockages from debris can disrupt performance. Regularly check and clean the strainer for best results. Proper strainer care minimizes pump strain and supports longevity.

Routine Check Guidelines

Inspecting Shurflo pump parts is critical for spotting issues early. Establish a routine to check:

- Electrical fittings for damage

- Liquid levels in the tank

- Hose integrity and fitting tightness

- The pressure switch’s functionality

Correcting loose fittings and checking switch performance enhances operation. Consistent care greatly extends your pump’s life.

Pump Winterization Guidelines

Preparing your pump for winter is essential to avoid frost damage. To winterize properly:

- Fully empty the Water tank

- Clear the plumbing of leftover Water

- Employ a non-toxic antifreeze to shield seals and components

Adhering to these guidelines safeguards your system against winter damage, avoiding high repair costs. It also prepares it for the upcoming season.

Recommended Replacement Parts for Shurflo Pumps

To keep your Shurflo pump operating at its best, quality replacement parts are essential. Key components from the Shurflo 2095 series are indispensable for system reliability. Consider vital components like pressure switches, diaphragms, and valves when replacing parts. Using real Shurflo parts secures reliable operation and prolongs system life.

Summary of Shurflo 2095 Replacement Components

A variety of Shurflo 2095 replacement components are available to address different needs. Their seamless integration improves efficiency and minimizes issues. Each piece is crucial for maintaining the pump’s efficiency.

- Pressure switches: Regulate the activation cycles of the Pump

- Diaphragms: Maintain proper Water flow and prevent leaks

- Valves: Regulate pressure and ensure smooth operation

Sources for Shurflo Spare Parts

For those in search of Shurflo parts, Installation Parts Supply is a reliable supplier. Their extensive inventory covers every aspect of Shurflo pump repairs and maintenance. Using authentic replacement parts helps maintain optimal pump function.

In Closing

Integral to reliable Water flow and long-lasting operation, the pressure switch is indispensable.

By grasping how it works, how to maintain it, and how to fix common problems, you can significantly enhance your Water system’s lifespan. This focus on maintenance can prevent common issues, boosting the Pump’s dependability, noted for its solid 4-year service streak.

Easy, budget-friendly upkeep is possible through interchangeable components for both 12V and 24V versions. Always verify part numbers—use 94-890-08 for the 12V and 94-890-09 for the 24V pressure switch to avoid needless costs and prolong your pump’s life.

Evidently, well-maintained Shurflo pumps exhibit exceptional reliability. Anticipate even greater performance from the newer models, which underscores the brand’s focus on quality. Trust Installation Parts Supply for professional installation assistance and authentic parts. Adhering to proper maintenance guidelines guarantees prolonged, efficient operation.